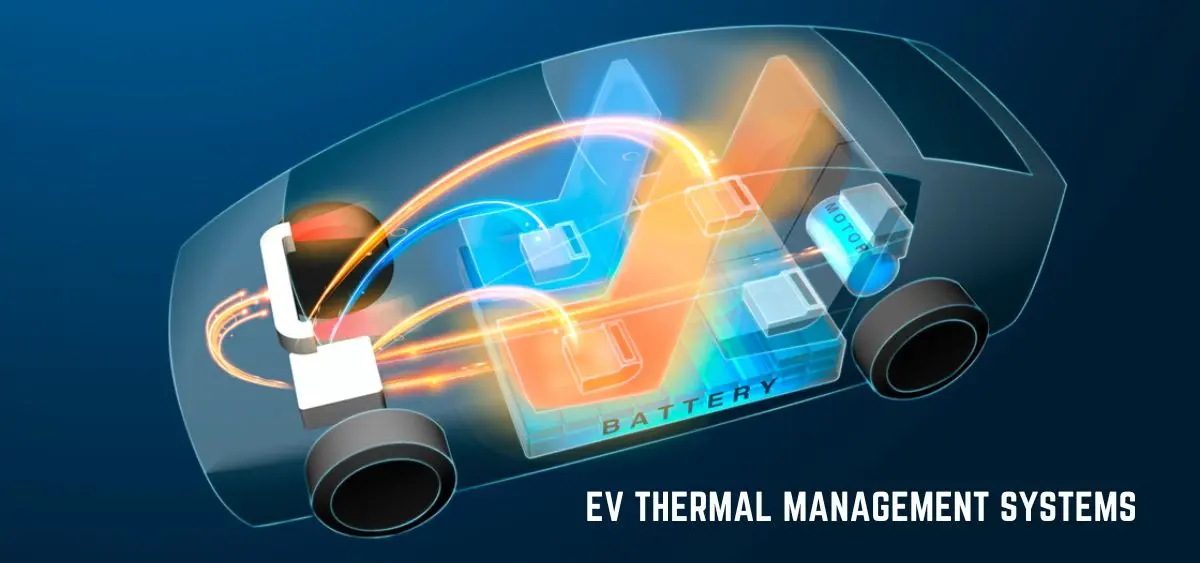

EV Thermal Management (EVTMS): The Critical Role of Battery Thermal Management in Electric Vehicles – How EVs Stay Cool!

In the world of electric vehicles (EVs), one of the most crucial yet often overlooked components is the EV Thermal Management System. While most people focus on range and speed, the ability to regulate battery temperature plays a vital role in maximizing performance and ensuring long-term reliability. But how do these systems keep EV batteries cool and efficient? What happens when temperatures aren’t managed correctly? In this article, we’ll dive into the fascinating technology behind EV thermal management, uncovering how it impacts everything from safety to charging speed, and why it’s a game-changer for the future of electric mobility.

Understanding EV Thermal Management (EVTMS)

Electric Vehicle Thermal Management Systems (EVTMS) are vital for regulating the temperature of key EV components, including the battery, motor, and passenger cabin. These systems ensure optimal performance, safety, and efficiency by maintaining ideal temperature levels across all conditions.

As electric vehicles generate less heat compared to traditional combustion engines, managing thermal balance becomes more complex. In colder environments, additional heating is required for passenger comfort, which can reduce driving range. During fast charging—especially with high-powered DC chargers up to 350 kW—battery temperature must be precisely controlled to avoid performance drops and safety issues.

Modern EVTMS includes a mix of battery cooling and heating systems, inverter cooling, and advanced HVAC units. Many automakers now adopt integrated, liquid-based thermal management solutions to ensure consistent battery temperature regulation.

Proper thermal control prevents potential issues such as battery degradation, insulation failure, reduced motor efficiency, and thermal runaway. The Battery Thermal Management System (BTMS), a core part of EVTMS, plays a key role in extending battery life, enhancing EV range, and ensuring driver safety.

In summary, effective EV thermal management is not just about keeping batteries cool—it’s about sustaining long-term vehicle performance, safety, and energy efficiency.

Key Functions of Electric Vehicle Thermal Management Systems (EVTMS)

Electric Vehicle Thermal Management Systems (EVTMS) play a critical role in maintaining the performance, safety, and comfort of electric vehicles (EVs). These systems regulate temperature across different components, ensuring optimal efficiency and reliability. Below are the key functions of EVTMS:

- Battery Thermal Management (BTM): Lithium-ion batteries, commonly used in EVs, are highly sensitive to temperature changes. Extreme heat or cold can reduce their efficiency, lifespan, and safety. Battery Thermal Management ensures that the battery pack operates within a safe temperature range. One effective method is liquid cooling, where a coolant circulates through the battery cells to remove excess heat.

- Motor Thermal Management (MTM): Electric motors generate significant heat during operation. Without proper cooling, performance can drop, and components may wear out faster. MTM helps maintain an ideal temperature, supporting consistent motor performance and durability.

- Cabin Climate Control Integration: EVTMS is often integrated with the vehicle’s cabin climate control system. It helps maintain a comfortable interior temperature for passengers without compromising the vehicle’s energy efficiency.

- Heat Recovery Systems: Advanced EVTMS units can capture excess heat produced by the battery or motor. This recovered heat can be used to warm the cabin, reducing the load on the HVAC system and improving the vehicle’s overall energy efficiency.

- Thermal Runaway Prevention: In the event of overheating, EVTMS plays a vital role in preventing thermal runaway—a hazardous situation where battery cells overheat rapidly, potentially leading to fire or explosion. Early detection and active cooling mechanisms help mitigate this risk.

Overall, EVTMS is essential for ensuring safety, extending component lifespan, and enhancing the driving experience in electric vehicles.

Types of Battery Thermal Management Systems in Electric Vehicles (EVs)

As electric vehicles (EVs) evolve, efficient battery thermal management systems (BTMS) are essential for ensuring performance, safety, and battery lifespan. These systems regulate battery temperature, especially during high charging or discharging rates. Below are the main types of BTMS used in EVs today:

- Air Cooling: Air cooling systems use external air to manage battery temperature. These systems are lightweight, cost-effective, and energy-efficient, making them ideal for low-cost EV models. However, due to the air’s low thermal conductivity, they offer limited cooling efficiency. Their performance also depends heavily on ambient temperature, and designing consistent airflow patterns inside the battery pack can be challenging.

- Liquid Cooling: Liquid-based systems circulate coolant (like water or glycol) through the battery pack for better heat dissipation. They offer superior cooling due to the higher thermal conductivity of liquids, but are more complex, heavier, and consume more power. These systems are often used in high-performance EVs and require pumps, pipes, and controllers to maintain flow. While efficient, they can reduce driving range due to added energy use.

- Phase Change Materials (PCM): PCMs absorb and store heat during phase changes (e.g., from solid to liquid), offering excellent temperature control. These passive systems require no energy to operate and ensure uniform temperature across battery cells. However, they are relatively heavy, costly, and may require supplemental cooling once their thermal limit is reached.

- Thermoelectric Cooling: This system uses thermoelectric modules to create a cooling effect. Though compact and reliable, they are currently limited in large-scale EV applications due to efficiency constraints.

- Hybrid Systems: Combining air, liquid, or PCM cooling methods, hybrid systems aim to balance efficiency, cost, and performance.

As the electric vehicle market expands, the demand for longer battery life and higher power output will continue to rise. To meet these demands, battery thermal management systems must effectively dissipate heat from the battery pack, especially as charging and discharging rates increase. The heat generated during battery operation can pose safety risks to passengers, making it crucial to use the appropriate coolant and additive package to handle the high temperatures produced by the batteries.

Why is the Electric Vehicle Thermal Management System (EVTMS) Important?

Have you ever noticed your phone battery drains faster in the cold or acts up on extremely hot days? The same concept applies to electric vehicle (EV) batteries. These high-performance batteries work best within a specific temperature range—ideally between 20°C and 30°C (68°F to 86°F). Temperatures outside this narrow window can negatively impact performance, lifespan, and safety.

Electric vehicles face a wide range of climate conditions, but thanks to advanced thermal management systems, battery temperatures are carefully regulated. These systems maintain optimal battery function whether it’s cold or scorching hot outside.

It’s not just external temperatures that pose a threat—EV batteries generate heat during regular use and even more so during fast charging. Without proper cooling, these batteries can reach 70°C to 100°C (158°F to 212°F), which risks a dangerous condition called thermal runaway, where the battery overheats uncontrollably.

Thermal management systems are essential for controlling these internal temperatures. In colder conditions, they also help warm the battery before charging can begin. Whether it’s dissipating heat in summer or preheating in winter, thermal management ensures safe, reliable, and efficient EV performance year-round.

- Enhances Driving Range: Maintaining ideal temperature levels in the battery and motor is crucial to optimizing the vehicle’s range. When components operate within their recommended temperature zones, energy efficiency improves, allowing the EV to travel farther on a single charge.

- Boosts Performance: EVTMS ensures that the powertrain, comprising the motor, inverter, and battery, functions at peak efficiency. Proper thermal regulation minimizes energy loss and allows the vehicle to deliver consistent and reliable performance, even under demanding conditions.

- Increases Safety: Thermal management systems are essential for preventing overheating, which can lead to serious risks such as thermal runaway, battery fires, or system failures. A well-functioning EVTMS safeguards both the vehicle and its passengers.

- Protects Battery Health: Consistently operating at extreme temperatures can degrade battery cells. By keeping the battery at optimal temperatures, EVTMS helps extend its lifespan and ensures long-term reliability.

- Supports Faster Charging: Battery temperature directly affects charging speed. If the battery is too cold or too hot, charging can slow down or even pause to protect the cells. EVTMS moderates these conditions, enabling quicker and safer charging cycles.

- Prolongs Vehicle Longevity: Heat accelerates wear and tear on electrical components. EVTMS reduces this impact by maintaining temperature stability, thereby prolonging the overall life of the vehicle.

How does BTMS work?

Battery Thermal Management Systems (BTMS) play a crucial role in electric vehicles (EVs) and energy storage systems by maintaining the ideal temperature for battery operation. Since batteries are sensitive to temperature changes, BTMS ensures they perform efficiently and safely in all conditions.

- Cooling the Battery System: When an electric vehicle is charging, discharging, or accelerating quickly, it generates significant heat. If this heat is not properly controlled, it can damage the battery cells and reduce their lifespan. The cooling component of BTMS helps remove excess heat using air cooling, liquid cooling, or phase-change materials. This prevents overheating and keeps the battery operating within a safe temperature range, which is essential for optimal performance and long-term durability.

- Heating in Cold Conditions: Cold weather can significantly reduce battery performance. In such conditions, batteries may become too cold to function properly, leading to reduced efficiency and capacity. The heating function in BTMS addresses this problem by warming the battery to reach its ideal operating temperature. This ensures smooth power delivery and reliable performance even in freezing environments.

- Maintaining Uniform Temperature: Another important feature of BTMS is its ability to maintain a consistent temperature across all battery cells. Uneven temperatures within the battery pack can lead to performance imbalance, accelerated wear, and even safety risks. By ensuring uniform temperature distribution, BTMS supports balanced cell performance, enhances battery safety, and extends the overall battery life.

In summary, BTMS is essential for regulating battery temperature during both hot and cold conditions. Its cooling, heating, and temperature-balancing functions are vital for improving efficiency, ensuring safety, and maximizing the lifespan of modern battery systems.

Key Benefits of Efficient EV Thermal Management

Electric vehicles (EVs) depend heavily on their battery systems. A well-designed Battery Thermal Management System (BTMS) plays a critical role in maintaining ideal battery temperature, which significantly impacts the overall performance, safety, and reliability of the vehicle. Here are the main advantages of effective thermal management in EVs:

- Longer Battery Life: Managing battery temperature helps avoid overheating and excessive cooling, two major factors that degrade battery health over time. A balanced thermal environment ensures the battery operates within a safe range, which extends its lifespan and delays the need for costly replacements.

- Better Vehicle Performance: When the battery remains at its optimal temperature, it can deliver consistent power more efficiently. This directly translates into better acceleration, improved energy efficiency, and maximum driving range, especially in extreme weather conditions.

- Enhanced Safety: Proper thermal management reduces the chances of thermal runaway—a dangerous condition where battery temperature increases uncontrollably. Preventing this risk helps avoid overheating incidents and potential battery fires, making EVs safer for everyday use.

- Faster Charging Capability: Batteries maintained at a suitable temperature can handle higher charging currents. This allows the battery to charge more quickly without damaging the cells, improving convenience for users and reducing overall charging time.

- Improved Reliability: By keeping the battery system in optimal condition, BTMS enhances the overall dependability of the vehicle. It ensures stable performance across varying temperatures, leading to fewer breakdowns and maintenance issues.

Cutting-edge solutions for thermal management in electric vehicles

Modern EV thermal management systems offer advanced diagnostic and protection capabilities while consuming minimal space and energy, ensuring enhanced vehicle performance.

- MOTIX™ 32-bit Motor Control SoC: The MOTIX™ system-on-chip (SoC), based on the Arm® Cortex®-M, integrates a 32-bit microcontroller, non-volatile flash, and a variety of analog and mixed-signal peripherals. It supports communication interfaces like CAN FD and is ideal for DC and BLDC motor applications, offering efficient motor control.

- TRAVEO™ T2G MCUs: The TRAVEO™ T2G microcontrollers, built on Arm® Cortex®-M4/M7 cores, offer superior human-machine interface (HMI) integration and support advanced networking protocols, optimizing control in automotive applications.

- Automotive PSoC™ 4: The PSoC™ 4 embedded microcontroller, based on the Arm® Cortex®-M0+ CPU, features programmable analog and digital blocks, flexible automatic routing, and reconfigurability, making it perfect for various automotive applications.

- XENSIV™ Magnetic Sensors: XENSIV™ sensors use 3D magnetic measurement with I2C for adaptable platform integration, enhancing precision in EV thermal management systems.

- OptiMOS™ Power MOSFETs: With best-in-class RDS (on) performance, OptiMOS™ power MOSFETs ensure high efficiency in the thermal management of EVs.

Heat sources in EVs

EV thermal management solutions are essential for maintaining performance, safety, and longevity. These solutions can be categorized into three main systems that manage heat effectively:

- Cabin HVAC System

- Ensures passenger comfort by regulating temperature.

- Composed of a refrigerant loop and an HVAC loop to manage cabin climate.

- Inverter Cooling System

- Essential for keeping the electric motor’s efficiency, durability, and safety intact.

- As the automotive industry adopts more electric vehicles, managing thermal issues related to power electronics and electric motors becomes critical.

- Challenges include maintaining compact designs, cost-effectiveness, low weight, and high reliability.

- Battery Cooling and Heating Systems

- Critical for enhancing battery life and preventing thermal runaway, ensuring safety.

- These systems include electric coolant pumps, valves, cooling fans, and electric/PTC heaters to maintain optimal battery temperature.

Additionally, several energy conversion processes in EVs generate heat and require efficient management:

- High to Low-Voltage DC Conversion: Used for powering peripheral systems.

- AC to DC Conversion: Occurs during charging via onboard chargers (OBC).

- Battery Charging and Discharging: Heat is generated, especially during rapid charging.

- DC to AC Conversion: Inverters convert DC from batteries to AC for traction motors.

EV Battery Thermal Management Challenges

Effective thermal management in electric vehicles (EVs) is crucial, yet it faces several challenges. Below are the key issues encountered with EV battery thermal management systems:

- Coolant Leaks: If the thermal management system uses liquid cooling, there’s a risk of coolant leaks as the battery ages. Even minor leaks can lead to battery degradation, impacting its performance and lifespan over time.

- Corrosion and Clogging

- Corrosion: Liquid glycol coolants can corrode cold plates, which transfer heat from the battery to the coolant. Regular replacement of the coolant can prevent this damage.

- Clogging: Narrow tubes and connections used in coolant transport can become clogged, reducing the system’s efficiency. Selecting the right coolant and changing it regularly can minimize clogging risks.

- Choosing the Right Coolant: Different coolants like pure water, deionized water, and dielectric fluids (e.g., perfluorinated carbons) offer various benefits. Pure water is effective for heat transfer and corrosion prevention, while dielectric fluids reduce the likelihood of electrical issues.

- Climate Conditions: Extreme temperatures can affect battery performance. The thermal management system must regulate the battery temperature to prevent overheating or freezing in hot or cold climates.

- Battery Aging: As batteries age, they generate more heat. The thermal management system must efficiently handle this excess heat to maintain performance throughout the battery’s life.

Future Developments in BTMS

Ongoing research and development in Battery Thermal Management Systems (BTMS) are focusing on several key areas for improvement:

- Advanced Thermal Materials: New thermal interface materials and composites are being developed to enhance heat transfer efficiency within battery packs, improving overall performance and longevity.

- AI and Machine Learning Integration: Implementing AI and machine learning algorithms can lead to more adaptive and predictive BTMS, optimizing cooling based on real-time driving conditions, weather forecasts, and individual usage patterns.

- Immersion Cooling: Researchers are exploring direct immersion cooling, where battery cells are submerged in dielectric fluids, offering a more efficient method for cooling high-performance applications.

- Vehicle-wide Thermal Integration: Integrating BTMS with broader vehicle thermal systems, including cabin climate control, could lead to more efficient energy management, reducing overall power consumption.

- Solid-State Battery Technology: The development of solid-state batteries holds potential to revolutionize BTMS, as these batteries have unique thermal characteristics and may require less cooling, enhancing efficiency.

FAQs: EV Thermal Management Systems

Where Does Heat Come from in Batteries?

The electric current going through batteries encounters resistance in various materials. As a result, some of the electrical energy is loss as heat. Resistance occurs during charging and discharging when the current passes through electrodes, electrolyte, current collectors, busbars, and various interconnections. The higher the current, the more heat is generated.

Why Are Batteries Affected by Temperature?

Batteries are affected by temperature changes because temperature impacts the kinetic energy of the molecules found in battery materials (such as the electrolyte and the electrodes). This makes these materials more or less conductive based on their temperature.

How do I keep my EV battery cool?

- Don’t Charge Your Battery Past 80%

- Allow Your Battery to Cool Down Before Charging.

- Avoid Driving in Extreme Temperatures.

- Use Air Conditioning and Heating Sparingly.

- Turn Off Unnecessary Features and Accessories.

Do EV batteries have cooling systems?

One of the critical components that ensures the efficient operation of EVs is the battery cooling system. Understanding how these systems work and why they are essential is crucial for anyone interested in EV technology.

Related Articles:-